Nizampura, Vadodara, Gujarat

- GST NO. : 24AAHFB6183E1ZM

Sulphuric Acid Plant

Leading Manufacturers, Exporters, Wholesaler, Retailer of Sulphuric Acid Concentration Plant, Sulphuric Acid Dilution Plant and Sulphuric Acid Manufacturing Plant from Vadodara.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Sulphuric Acid Plant |

| Voltage | As Per Requirement |

| Capacity | As Per Requirement |

| Automatic Grade | As Per Requirement |

| Power | As Per Requirement |

| Driven Type | As Per Requirement |

| Product Code | SAC |

Preferred Buyer From

| Location | Worldwide |

We have firmly positioned ourselves as one of the dependable Sulphuric Acid Plant Manufacturers and suppliers based in India. We deal in two types of Sulphuric Acid Chemical Plant that includes :

- Sulphuric Acid Concentration plant

- Sulphuric Acid Dilution

Sulphuric Acid Concentration Plant

Sulphuric acid is used in many processes in chemical plants, thus making spent acid quite diluted. Disposing of this spent acid becomes an environmental pollution problem besides a waste of precious resource. The diluted spent acid can be efficiently re-concentrated up to a maximum concentration of 96% (w/w) and reused in the main plant process, thus saving the environment and that too by improving the economical bottom line. Thus, sulphuric acid recovery or concentration plant is a fantastic option for high sulphuric acid users in process plants.

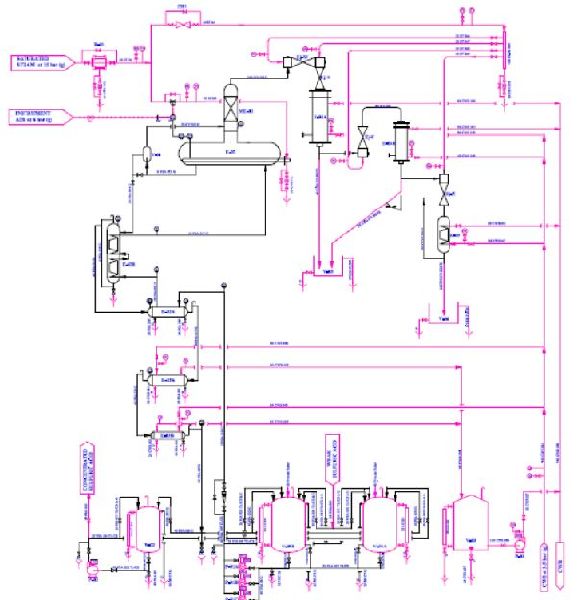

Concentration of Sulphuric acid is mostly performed under vacuum in order to reduce the operating temperature, especially for high concentrations. We offer turnkey solutions right from know-how & technology, to supply, installation & commissioning. Our plant comprises of equipments wherin the wetted parts are made up of Borosilicate glass 3.3, Fluoropolymers (PTFE, PFA, FEP, PVDF, PP, etc), High Nickel alloys, Graphite & exotic metals (Ta, Ti, Nb, etc.).

The plants can be totally automated by PLC or DCS based systems and even integrated with computers (SCADA etc).

Sulphuric Acid Dilution

Sulphuric acid is a heavy chemical and finds numerous applications in the industry. It is the product of ‘Contact Process’ and commercially available as 98.5% (w/w) H2SO4 or stronger in the form of oleum.

However, many of the processes and applications utilizing sulphuric acid require weaker acid than this. As a result, dilution equipment is often necessary in order to meet the requirement for this weaker acid.

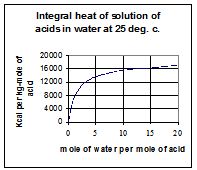

During dilution, considerable heat is generated depending on the extent of dilution desired. The Integral heat of solution of sulphuric acid is plotted in fig.1. The heat liberated sometimes is sufficient to produce boiling of the acid and so, provision is made for the re-circulation of a portion of cooled dilute acid, thus ensuring working at controlled temperature.

From the above it will be clear that intimate mixing and efficient heat transfer form the pre-requisites for sulphuric acid dilution unit to avoid excessive temperature and local heating and uniform product concentration.

Process Description

Metered quantity of sulphuric acid is introduced to a heat exchanger with re-circulation of water through a pump from the tank containing pre-determinant quantity of water. The turbulence created in the heat exchanger ensures both intimate mixing and efficient heat transfer. When desired strength of acid is reached, the contents of the tank are transferred to storage and fresh batch can be started again.

Benefits of Industrial Sulphuric Acid Plant

- High product quality is guaranteed, as glass is completely inert to sulphuric acid

- Available in wide range of concentrations and capacities

- Simple and easy to operate

- Operational reliability due to maintenance free in working

- Corrosion Resistant

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Sulphuric Acid Plant |

| Weight | As Per Requirement |

| Voltage | As Per Requirement |

| Capacity | As Per Requirement |

| Automatic Grade | As Per Requirement |

| Power | As Per Requirement |

Preferred Buyer From

| Location | Worldwide |

Sulphuric acid is a heavy chemical and finds numerous applications in the industry. It is the product of ‘Contact Process’ and commercially available as 98.5% (w/w) H2SO4 or stronger in the form of oleum.

However, many of the processes and applications utilizing sulphuric acid require weaker acid than this. As a result, dilution equipment is often necessary in order to meet the requirement for this weaker acid.

During dilution considerable heat is generated depending on the extent of dilution desired. The Integral heat of solution of sulphuric acid is plotted in fig.1. The heat liberated sometimes is sufficient to produce boiling of the acid and so, provision is made for the re-circulation of a portion of cooled dilute acid, thus ensuring working at controlled temperature.

From the above it will be clear that intimate mixing and efficient heat transfer form the pre-requisites for sulphuric acid dilution unit to avoid excessive temperature and local heating and uniform product concentration.

Process Description :

Metered quantity of sulphuric acid is introduced to a heat exchanger with re-circulation of water through a pump from the tank containing pre-determinant quantity of water. The turbulence created in the heat exchanger ensures both intimate mixing and efficient heat transfer. When desired strength of acid is reached, the content of the tank is transferred to storage and fresh batch can be started again.

System Benefits :

1.High product quality is guaranteed as glass is completely inert to sulphuric acid.

2.Available in wide range of concentrations and capacities.

3.Simple and easy to operate.

4.Operational reliability due to maintenance free in working.

5.Corrosion Resistant

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Sulphuric Acid Plant |

| Weight | As Per Requirement |

| Voltage | As Per Requirement |

| Capacity | As Per Requirement |

| Automatic Grade | As Per Requirement |

| Power | As Per Requirement |

Preferred Buyer From

| Location | Worldwide |

BVR Provides complete turnkey solutions for the manufacturing plant projects of Sulphuric acid from Sulphur & allied products, for commercial and laboratory grades.

Our services include preparation of preliminary estimation, pre-feasibility reports, DPR, Plant technology, know-how, basic & detail engineering, project execution, procurement, fabrication, erection supervision and plant commissioning.